Page 3 of 26

The Gearhead Thread

Posted: 26 Apr 2022, 19:58

by joegoat

FredS wrote: ↑26 Apr 2022, 14:40

JudgeRusty wrote: ↑26 Apr 2022, 14:20

FredS wrote: ↑26 Apr 2022, 13:45

Hopefully taking off the couplings, springs and t-latch for a clean up does the trick. Are you sure the sickle bar moves freely in it's track? I think that ball and socket coupling is designed to pop apart if you try to mow trees or something. A worm clamp might hold it together but it might break the next weakest link.

I thought the same thing, that's why I am saving the clamp notion as a last resort. As mentioned, I removed the knife and used a wire brush to shine all friction pieces during the last repair attempt. I filed the rough spots off the blades and greased the knife

I pulled a string to check for true. I have ruled out some issues like the pitman arm timing as it was supposed to be in running order when last parked.

Court today, also rain, but maybe work on it tomorrow after work.

One wonders if it pops out when running on flat ground or only when the bar is tilted up/down (relative to the tractor and hitch) for the dam/ditch.

I thought the angle might be an issue because they were designed for use in a flat hayfield, but we ran a sickle bar along the roadsides on the farm. It didn't lay flat for that. I can't remember who made it though.

The Gearhead Thread

Posted: 27 Apr 2022, 05:34

by JudgeRusty

joegoat wrote: ↑26 Apr 2022, 19:58

FredS wrote: ↑26 Apr 2022, 14:40

JudgeRusty wrote: ↑26 Apr 2022, 14:20

I thought the same thing, that's why I am saving the clamp notion as a last resort. As mentioned, I removed the knife and used a wire brush to shine all friction pieces during the last repair attempt. I filed the rough spots off the blades and greased the knife

I pulled a string to check for true. I have ruled out some issues like the pitman arm timing as it was supposed to be in running order when last parked.

Court today, also rain, but maybe work on it tomorrow after work.

One wonders if it pops out when running on flat ground or only when the bar is tilted up/down (relative to the tractor and hitch) for the dam/ditch.

I thought the angle might be an issue because they were designed for use in a flat hayfield, but we ran a sickle bar along the roadsides on the farm. It didn't lay flat for that. I can't remember who made it though.

No testing yet in ditches or down pond bank. I set it up per manual measuring ground to hitch pin distances and with knife level. It operates well at low rpm and not in grass, but fails in grass or with higher rpm. ( The low rpm being 300-400 which is below optimum cutting speed of 500-900.)

The Gearhead Thread

Posted: 27 Apr 2022, 09:08

by Jocose

Edit

The Gearhead Thread

Posted: 27 Apr 2022, 10:16

by Biff

Jocose wrote: ↑27 Apr 2022, 09:08

This has FredS written all over it.

No it doesn't. It has ""Me. My useless knowledge about cars" written all over it.

The Gearhead Thread

Posted: 27 Apr 2022, 10:42

by Jocose

Edit

The Gearhead Thread

Posted: 27 Apr 2022, 11:09

by JudgeRusty

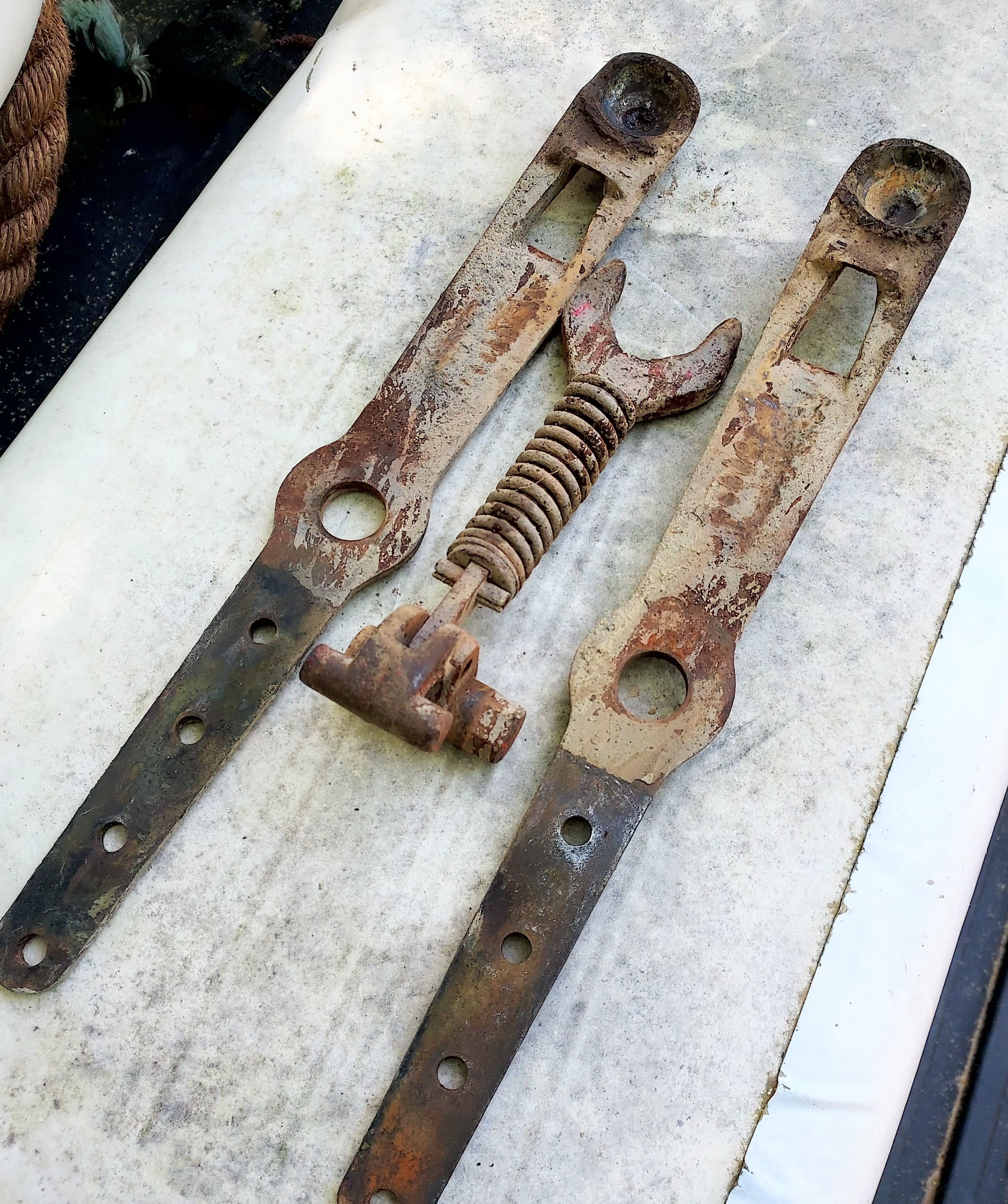

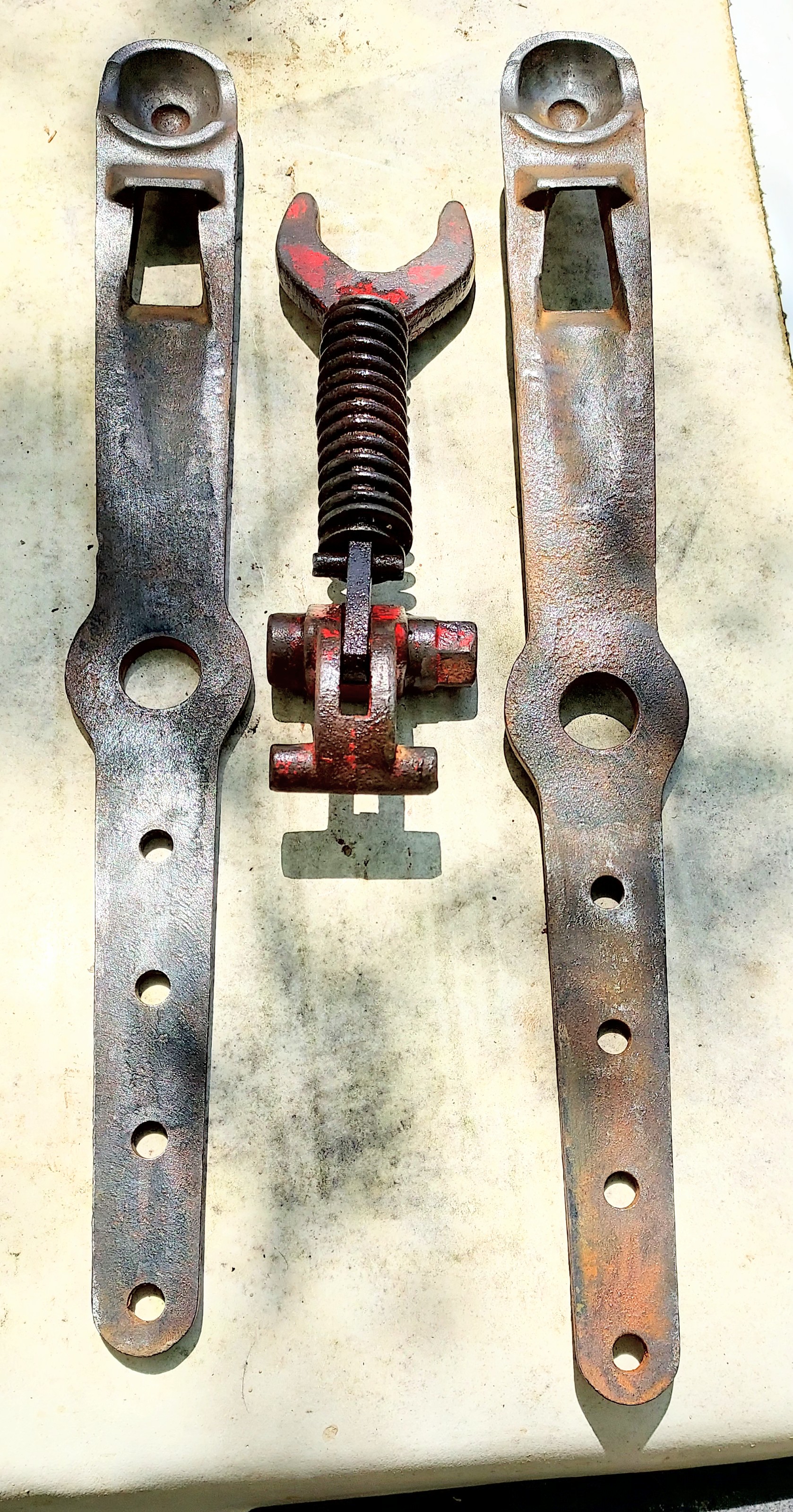

Before and after pics of quick detach ball joint clamp.

Ready to reassemble and give it another try.

- 20220427_120125~2.jpg (1.77 MiB) Viewed 264467 times

- 20220427_120147~2.jpg (1.82 MiB) Viewed 264467 times

- 20220427_124025~2.jpg (1.58 MiB) Viewed 264467 times

The Gearhead Thread

Posted: 27 Apr 2022, 18:13

by joegoat

JudgeRusty wrote: ↑27 Apr 2022, 11:09

Before and after pics of quick detach ball joint clamp.

Ready to reassemble and give it another try.

How much play is in the ball joint and clam shells? A lifetime of poor lubrication and grit could have worn it to the point where it can spread enough to separate.

The Gearhead Thread

Posted: 27 Apr 2022, 18:25

by JudgeRusty

joegoat wrote: ↑27 Apr 2022, 18:13

JudgeRusty wrote: ↑27 Apr 2022, 11:09

Before and after pics of quick detach ball joint clamp.

Ready to reassemble and give it another try.

How much play is in the ball joint and clam shells? A lifetime of poor lubrication and grit could have worn it to the point where it can spread enough to separate.

Mowed with reassembled ball joint without separation. However, vibrated some old bolts loose so back to shade tree for more work but making progress.

The Gearhead Thread

Posted: 28 Apr 2022, 05:33

by FredS

The Gearhead Thread

Posted: 13 May 2022, 21:36

by sweetandsour

I took the tire off of my grandsons F-150 and the outer brake pad was completely gone. The rotor was beyond gouged. We replaced the rotor, put on the new pads, but can't get the pistons compressed back in, they're stuck/seized completely extended and we can't budge them, even with the brake bleed stem open. Any ideas? Or should we just buy new calipers. It's another $200 if we replace both front calipers.